What Is a Telehandler? Uses and Benefits of This Versatile Machine

The equipment you select has a massive impact on the success of a project. The telehandler stands out among the machines available.

To people who don’t dabble in yellow iron, a telehandler might appear as just another heavy-duty machine. However, for industry veterans, its value is undeniable. With its unique design and wide range of capabilities, the telehandler has earned its spot on job sites, from bustling urban developments to expansive agricultural fields.

Understanding a telehandler means more than recognizing its form or basic operations. It means knowing how it affects workflow, productivity, and safety.

Defining a Telehandler

At first glance, a telehandler might be mistaken for a forklift or a loader. However, when you notice its versatile boom extending outward or upward, its uniqueness becomes obvious.

What primarily distinguishes a telehandler from other machines is this extendable boom. Unlike a traditional forklift with a straightforward mast designed for vertical lifting, a telehandler's boom can extend forwards and upwards, offering height and reach. This allows it to perform tasks requiring multiple machines, from lifting heavy loads to elevated platforms to placing materials far away from the machine.

The versatility of the telehandler has led to it being called by various names, depending on its use or region. Commonly, it's referred to as a "telescopic handler" owing to its extending arm. In some contexts, especially when fitted with specific attachments, it might be known as a "boom loader." Regardless of the name, the core principle remains the same: a multipurpose machine designed to navigate diverse challenges on a job site.

Key Features of a Telehandler

At the heart of the telehandler's appeal is its unique design and the features that equip it for various tasks. Here are some of the primary components and functionalities that make this machine a standout:

The telehandler's most noticeable feature is its boom. This extendable arm can reach forward and upward, granting the machine a degree of flexibility that few other pieces of equipment can match. Depending on the model and design, this boom can stretch several meters, enabling the telehandler to access high or distant locations easily.

One of the reasons telehandlers are so adaptable is because of the attachments available. With a quick switch, a telehandler can transform from a machine lifting pallets to scooping up loads of dirt. Some of the common attachments include:

The most compelling feature of the telehandler is its versatility. Whether lifting materials onto a tall building or repairing infrastructure, the telehandler is easily adaptable. Its ability to adapt to various roles means you can potentially do more with one machine.

A telehandler's features and adaptability make it a staple in diverse industries, renowned for its ability to streamline tasks and enhance productivity.

Diverse Uses of Telehandlers

The telehandler's adaptability is reflected in its widespread application across multiple industries. From lifting to reaching, from stacking to loading, the machine's multifunctional capabilities have established it as a go-to choice for various tasks. Let's delve into some of its primary uses across different sectors:

In the bustling environment of a construction site, the telehandler proves invaluable in numerous ways:

Lifting Heavy Materials: Whether transporting bricks to a higher floor or positioning steel beams, the telehandler effortlessly manages heavy loads.

Site Cleanup: Post-construction, telehandlers equipped with buckets can assist in cleaning up debris, making site cleanup more efficient.

Positioning Equipment: Need to get that generator to the rooftop? A telehandler can come to the rescue.

The modern farm isn't just about plows and tractors. Telehandlers have found a prominent place in agricultural settings, offering a unique blend of versatility, power, and reach. Here's a closer look at their contributions:

Thanks to its robust lifting capabilities, a telehandler can pick up multiple hay bales simultaneously, significantly speeding up the stacking process.

Barns and storage sheds often require stacking bales up high. The extendable boom of the telehandler makes reaching these heights simple and safe, allowing for maximum use of storage space.

Telehandlers, equipped with specialized bale grip attachments, allow for the exact placement of bales, reducing the risk of toppling stacks and wasted feed.

From sacks of feed to heavy agricultural tools and machinery, telehandlers serve as the go-to machine for loading and unloading a variety of farm essentials.

Depending on what needs to be moved, operators can easily switch between forks, buckets, or grapple attachments, making the process seamless and efficient.

Manual loading and unloading can be labor-intensive and time-consuming. With telehandlers, farmers can handle larger quantities with less effort, saving both time and labor costs.

Equipped with a bucket attachment, telehandlers can carry and distribute a lot of feed in a single pass, catering to large herds or flocks.

The machine's ability to spread feed ensures an even distribution across feeding areas, ensuring all animals get their share, and accurate dispensing means less feed spills onto the ground, reducing waste and ensuring a more economical feeding process.

Warehouses, factories, and other industrial sites utilize telehandlers for a range of operations:

In large manufacturing facilities, telehandlers facilitate the movement of heavy machinery components, ensuring seamless production flow.

With bucket attachments, telehandlers can move substantial quantities of raw materials, such as sand, gravel, or even granular products in bulk.

Using forklift tines, telehandlers can transport stacks of goods stored on pallets, making inventory management efficient.

Warehouses often have shelves that are several meters high. Telehandlers, equipped with a man-basket or forklift attachment, can easily access these high spots, aiding in both stocking and retrieval processes.

Industrial settings often have hard-to-reach areas, like elevated pipelines, lighting fixtures, or ventilation systems. Telehandlers can be equipped with platforms that allow maintenance crews to reach and work on these installations safely.

Telehandlers are invaluable in maintenance and repairs due to their versatility in accessing hard-to-reach areas with their telescopic booms and their ability to handle various tasks, from lifting heavy equipment to safely elevating workers, thanks to various interchangeable attachments.

Access to Hard-to-Reach Areas: Due to their telescopic booms, telehandlers can extend to significant heights, allowing workers to access hard-to-reach places, such as rooftops, elevated machinery, or tall structures. This capability is particularly useful for HVAC maintenance, gutter cleaning, or roof repairs.

Moving Equipment: If machinery or equipment needs to be replaced or repaired, a telehandler can easily lift and transport these heavy items. This is particularly handy in industrial settings where large machinery parts might need replacement.

Safe Work Platforms: Some telehandlers can be equipped with a work platform attachment, converting the machine into a mobile elevated work platform (MEWP). This allows technicians to safely conduct repairs or maintenance at height, with the added benefit of moving the platform to different locations as needed.

Material Handling: During repair or maintenance projects, there might be a need to transport materials like tools, spare parts, or consumables to the site. The forklift attachment on a telehandler can easily carry these materials, especially in areas where traditional forklifts might struggle due to uneven terrain.

Site Cleanup: After maintenance or repair tasks, the site often requires cleanup. Telehandlers equipped with bucket attachments can help in removing debris, waste, or other materials from the site.

Electrical and Utility Repairs: For maintenance tasks related to electrical lines, telecommunication towers, or utility poles, telehandlers can offer a stable platform for technicians to work safely, especially when dealing with high-voltage equipment.

Infrastructure Repairs: For maintenance of bridges, tunnels, or other infrastructure elements, telehandlers provide an invaluable service in both reaching the areas in need of repair and transporting heavy materials or equipment.

In the transportation industry, especially within airports, telehandlers play a crucial role in streamlining operations and ensuring timely maintenance and logistics.

Aircraft Maintenance: Telehandlers, equipped with specialized attachments or work platforms, can elevate maintenance crews to specific parts of aircraft and transportation stations, facilitating inspections, repairs, or cleaning of areas that are otherwise difficult to access.

Cargo Handling: While many airports use specialized equipment for unloading and loading cargo planes, telehandlers can serve as a versatile backup, especially when handling oversized or irregular cargo items that might not fit traditional conveyor systems or require a more delicate touch.

Ground Maintenance: Airports encompass vast areas that require regular upkeep. Telehandlers can be used for tasks like lifting heavy machinery or materials and aiding in the repair of lighting systems, fences, or other infrastructure elements.

Emergency Response: In the unfortunate event of emergencies, telehandlers can be deployed for various roles, from aiding in rescues to helping clear debris.

Benefits of Using a Telehandler

The telehandler is a staple in industries ranging from construction to agriculture, and it's not just because of its impressive looks or robust design. This machine offers tangible benefits that make work processes more streamlined, safe, and effective.

The telehandler shines brightest in its adaptability. The machine's design allows for easy swapping of attachments, enabling it to transition from a forklift one moment to a bucket loader the next. Whether lifting pallets, scooping debris, or even operating it with a crane attachment, the telehandler is ready to tackle what you throw at it.

In many scenarios, the telehandler can replace the need for several other pieces of equipment. Teams can often just utilize a telehandler with the right attachment instead of juggling between a crane, forklift, and loader. This speeds up tasks and can lead to significant cost savings in equipment rentals, training, and maintenance.

While all heavy machinery requires careful operation, the telehandler offers safety advantages. Its design emphasizes stability, especially when lifting heavy loads or reaching maximum extension. Many models also come equipped with advanced safety features, such as load management systems, ensuring that operators and those around them are not at risk. Compared to some alternatives, the telehandler's enhanced lifting capabilities and stability can provide safety assurance on the job site.

Telehandler Safety Tips

Operating heavy machinery, like telehandlers, comes with inherent risks. However, with the right knowledge and practices in place, these risks can be significantly mitigated. The safety of operators and those around the job site should always be a top priority. Here are some key safety tips to keep in mind when working with telehandlers:

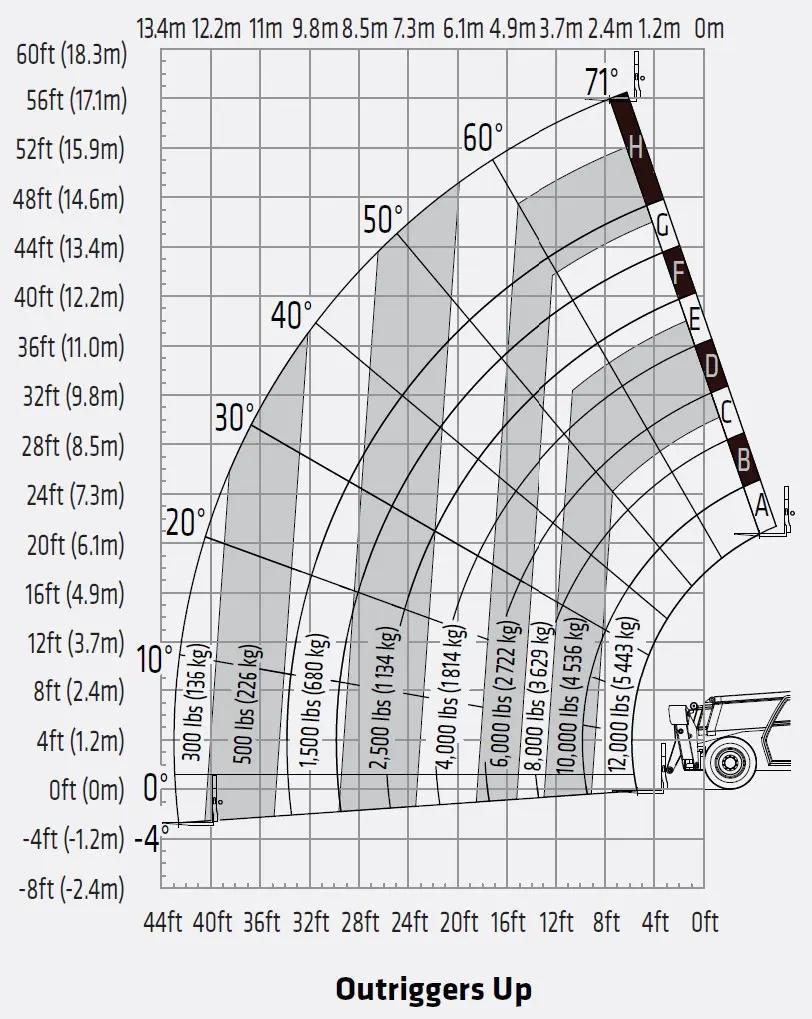

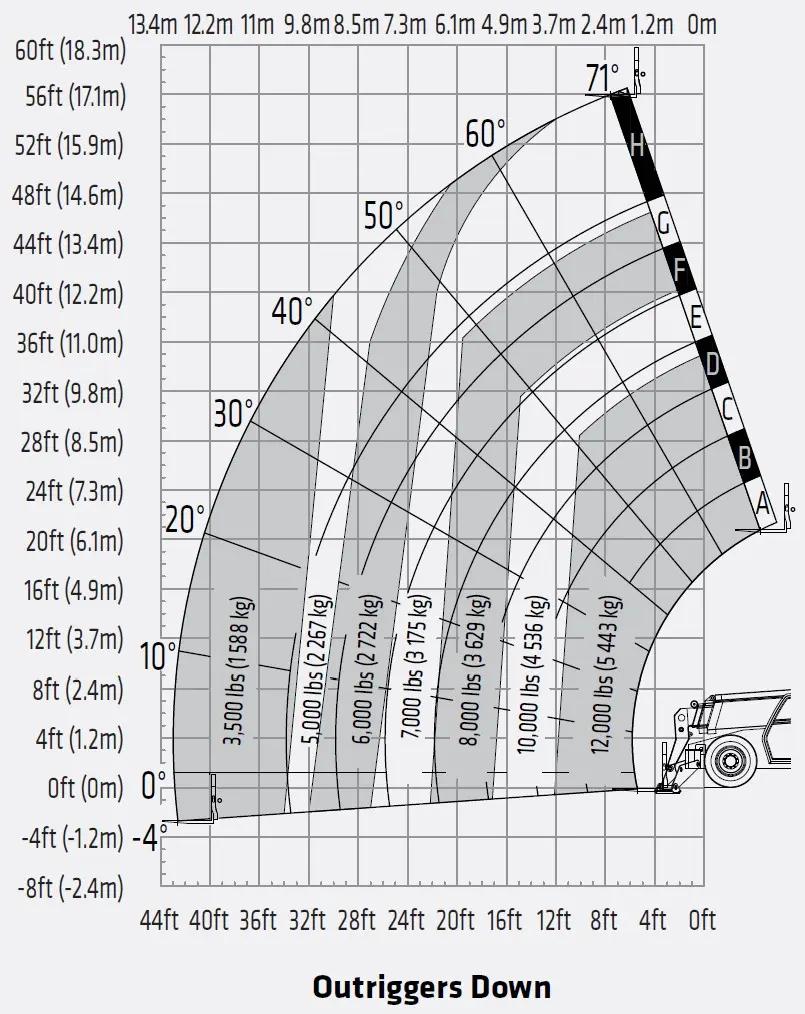

Load charts provide operators with essential information about the telehandler's lifting capacities at various heights and boom angles. Misinterpreting or ignoring this data can overload the machine, posing severe safety risks. Always consult the load chart before lifting and ensure that the weight of the load does not exceed the specified capacity for the given situation.

Before anyone gets behind the controls of a telehandler, they should undergo thorough training. This training should cover the basics of machine operation and delve into specific safety procedures, potential hazards, and best practices. Periodic refresher courses can also ensure operators stay updated with the latest safety guidelines.

Like any heavy machinery, telehandlers require regular maintenance to maintain optimal working conditions. This includes routine checks of hydraulic systems, brakes, tires, and other critical components. A well-maintained machine performs better and is less likely to encounter unexpected issues that could pose safety risks.

Before each use, operators should perform a quick visual inspection and walkaround of the telehandler. Check for damage, ensure all controls function correctly, and verify that safety systems are operational. This proactive approach can help identify potential issues before they become significant problems.

Telehandler vs. Other Machines

At a glance, a telehandler might resemble several other types of heavy machinery. Sometimes, people even refer to telehandlers by these other names. However, while overlapping functions exist, each machine has distinct advantages and optimal use cases.

While both machines can lift and transport loads, forklifts are primarily designed for moving goods at ground level or stacking them in warehouses. In contrast, telehandlers boast a telescopic boom, enabling them to reach greater heights and distances.

Both can be equipped with forks for pallet lifting, making them valuable assets in material handling.

Cranes are specialized for lifting heavy loads to great heights, especially in construction projects. Telehandlers, while versatile, may not offer the same height and weight capabilities as large cranes.

With the right attachments, telehandlers can also function in lifting roles similar to cranes, especially in smaller job sites or tasks that don't demand extreme heights.

Boom lifts (also known as cherry pickers) are designed to lift workers to heights safely. They aren't meant for heavy material handling. Telehandlers, on the other hand, focus on material handling but can be equipped with platforms to elevate workers.

Both feature a boom that can extend to elevate loads or workers to different heights.

Telehandlers shine in scenarios demanding versatility. A telehandler might be the most efficient choice if a job site requires both material handling and the elevation of workers or if materials need to be placed at varying heights and distances. Their adaptability, thanks to a wide range of attachments, makes them a go-to option in many construction, agricultural, and industrial settings. However, dedicated machines like cranes or boom lifts might be more appropriate for highly specialized tasks, like lifting extremely heavy loads to significant heights or elevating workers for detailed work at great heights.

While telehandlers offer a jack-of-all-trades solution in many scenarios, it's essential to assess the specific requirements of each job to determine the most suitable machine.

Wrapping It Up

Telehandlers have firmly established themselves as indispensable tools in construction, agriculture, and various other sectors. Their versatility and powerful lifting and reaching capabilities make them more than just another piece of machinery; they're game-changers on any job site.

Whether it's the adaptability of switching between attachments or the safety and efficiency they bring to projects, telehandlers consistently prove their worth. If you're on the fence about adding one to your fleet, keep exploring their uses.

Renting or investing in a telehandler could be the decision that increases your productivity to new heights (pun intended). Remember, the more you know about this versatile machine, the better equipped you'll be to harness its full potential.